The process of making scotch is actually quite easy, it’s just like making beer except you distill it a few times to get the clear whiskey, then put it into an Oak barrel to mature. The “making beer” part is actually pretty straightforward too, though the specifics can get a little complicated. In the next few articles I’ll discuss the individual steps but here’s the overall process.

First, you grow barley. When it’s ready, you pick it and put it in some hot water to let it germinate a bit. Once it has sprouted, you dry it in out a kiln. The germination produces the sugars that will be consumed by the yeast to produce alcohol later on. Once you roast it in a kiln, you grind it up with a grist mill and mix it with hot water, thus creating a mast ton. You drain and refill it several times to create the wort. Once the wort cools, you pitch in the yeast and let the little guys do their magic. Up until this point, the process could easily be mistaken for brewing beer (except you probably wouldn’t use peat to heat the kiln in drying the barley). After fermentation, the wort is now known as wash.

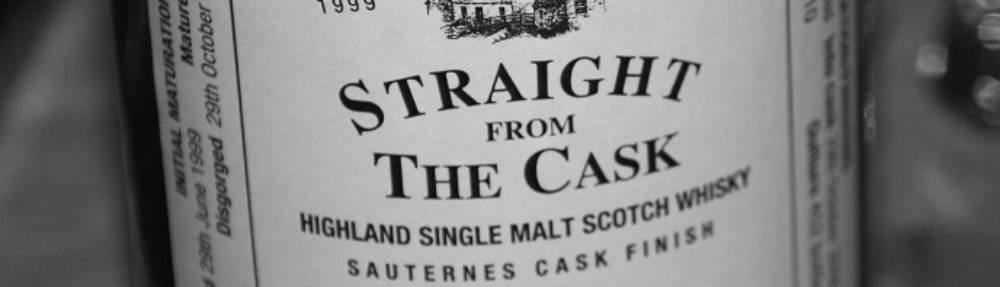

From here, once the wort has fermented to wash, the mixture is put into a pot still or a column still for distillation. The wash is distilled several times (2-3 usually) and part of the distilled whiskey is then put into an Oak barrel to be aged. After aging in a warehouse for many years, it’s then bottled (often after mixing with water to lower the alcohol by volume to a more reasonable 40-45%).

That, my friends, is the process of making scotch at a very high level.